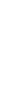

Typically, insulated shipping containers encompass:

(a) An external cardboard box. This box presents the product logo, labels and shipping information. It also adds an extra-layer for thermal protection, adds physical strength to the package, and allows palletisation of several packages for transportation and storage.

(b) Thermal insulation. Insulation protects the product against transmission of heat through the walls of the package. Examples of insulation are: combinations of corrugated fibreboard boxes with EPS foam panels, polyurethane foam, vacuum panels and loose fills (e.g. glass, alumina-silica, perlite, silica,aerogel and adiatomaceous earth, which are packed into gaps between the product and the external carboard box). The most popular embodiment of insulation is the humble polystyrene esky.

(c) A cooling (temperature control) agent. Among the most popular are: dry ice, wet ice, or gel packs that are manufactured with paraffin oils, salt hydrides or polyethylene glycol. All these substances act in the same manner: they change from one physical form to another at a certain temperature, absorbing latent heat from their surroundings in the process. This is why these agents are often called phase-change materials, or PCMs. However, some substances are more effective than others as cooling agents.Table 1 below presents a summary of advantages and disadvantages of dry ice, wet ice and gel ice packs.

(d) A temperature monitor. These can range from sophisticated electronic data loggers coupled with RFID to simple labels that change colour when a threshold temperature has been exceeded.

(e) Bubble wrap. Delicate products such as vaccines, flowers, tropical fruits and live seafood need to be kept cold, while avoiding at the same time superficial freezing through direct contact with the cooling agent.

(f) Dessicants. These are normally used to absorb any condensation inside the package, thus avoiding moisture damage to the product’s individual packaging and also any risks of microbial growth inside the package. Some shipping containers will have a radiation shield (e.g. aluminium foil) in the external and internal walls of the container. In well designed packages, this practice is effective in decreasing the amount of heat entering the package. However, the expense of adding the shield may increase the cost of the package considerably.

Gel Ice Pacs

How Gel Ice Works